Magnetic separation is used to separate solid mixtures containing magnetic and non-magnetic components. The separation technique relies on the magnetic properties of certain materials, which allows them to be attracted to magnets.

In a magnetic separation process, a mixture containing magnetic and non-magnetic materials is brought closer to a magnetic or a magnetic field. The magnetic materials are attracted to the magnet and are separated from the non-magnetic materials, which remain behind unaffected.

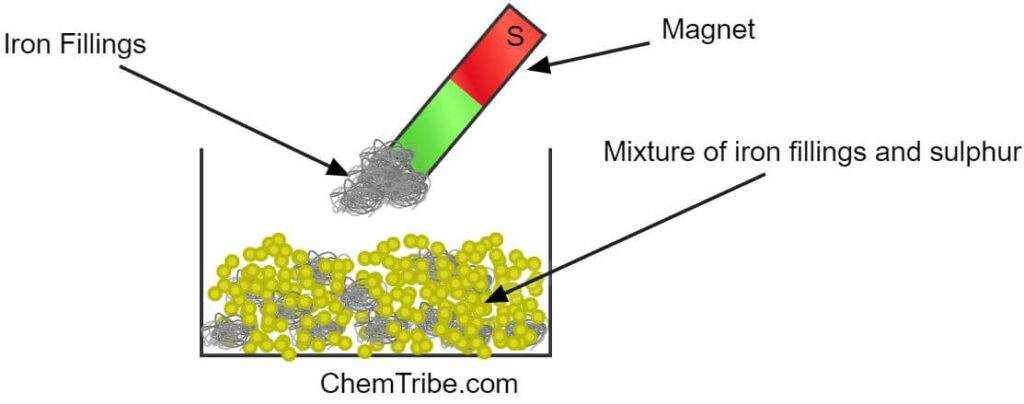

Separating a Mixture of Iron Fillings and Sulphur

A perfect example of a mixture that can be separated by magnetic separation is a mixture of iron fillings and Sulphur.

If you spread a mixture of iron fillings and sulphur on a piece of white paper and hold a magnet above the mixture, grey particles are attracted to the magnet leaving a yellow powder on the paper.

The grey substance attracted to the magnet is iron fillings while the yellow substance left on the paper is sulphur. The separation is possible because iron is magnetic while sulphur is non-magnetic.

Practical Applications of Magnetic Separation

- In recycling plants, magnetic separation is used to separate scrap iron from other materials such as plastics and other non-magnetic metals.

- In iron mining, magnetic separation is used to separate magnetic iron ore from other materials in the crushed ore.

- In the food industry, magnetic separation is used to remove ferrous contaminants from food products, such as grains, flour, and sugar.

- In biotechnology and medical research industries, magnetic separation is used for the isolation and purification of biomolecules, such as DNA, RNA, proteins, and cells. Magnetic beads coated with specific ligands are used to selectively bind target molecules for separation purposes.

- In water treatment facilities, magnetic separation is used to eliminate magnetic impurities like iron and manganese from water sources. A good example is this company that uses a system known as Flocculation Magnetic Separation. In this system, suspended solids in the raw water are combined with a flocculent containing magnetic powder, making them to clump together (flocculate). These clumps are then separated from the water using a permanent magnet.